In the ever-evolving world of electrical engineering, innovation knows no bounds. One such groundbreaking invention that has been turning heads in recent times is the busbar bending machine. This marvel of modern technology has revolutionized the way we handle electrical conduits, making it an indispensable tool for professionals in the field.

The Busbar Bending Machine boasts an exceptional level of precision and efficiency that was previously unheard of in the industry. Its computer-controlled bending mechanism allows for the accurate and repeatable shaping of busbars, which are essential components for distributing electrical power within switchgear and control panels. This newfound precision translates to fewer errors and enhanced safety in electrical installations, saving both time and resources.

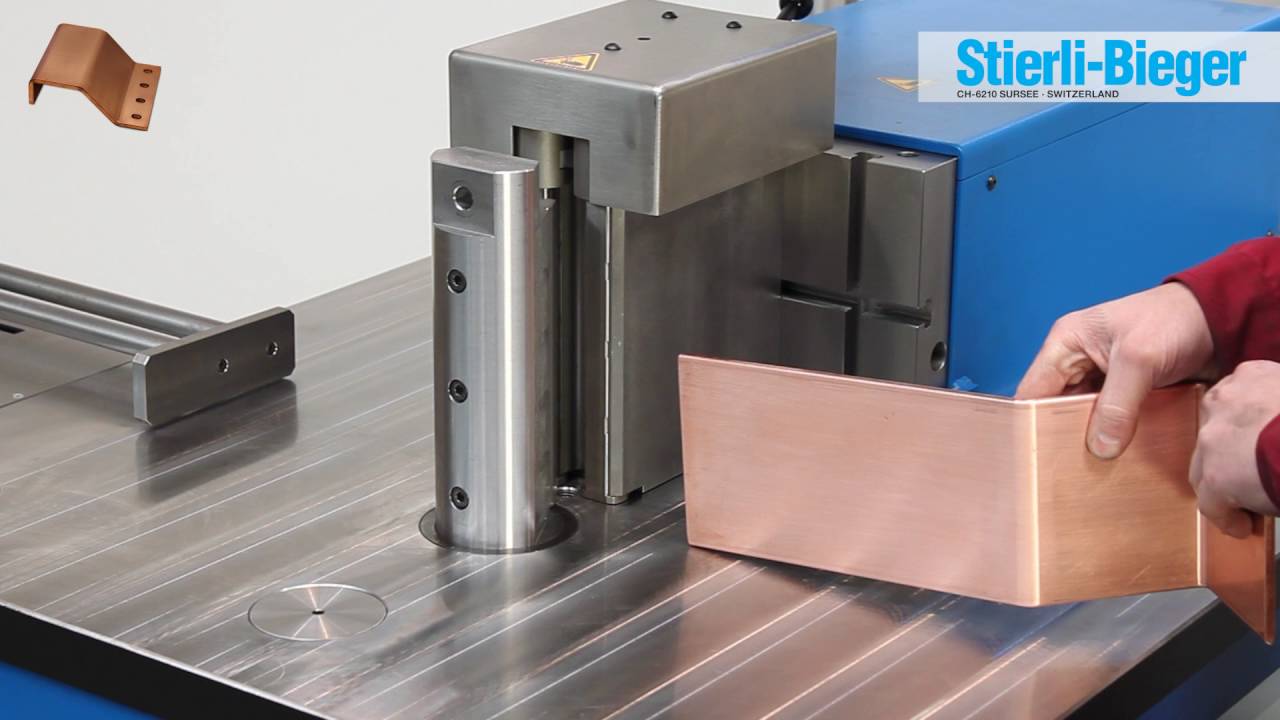

What truly sets the Busbar Bending Machine apart is its versatility. It can bend busbars of various sizes and shapes, accommodating the diverse needs of different projects. Whether it’s a simple 90-degree bend or a more complex configuration, this machine can handle it with ease. This versatility opens up a world of possibilities for electrical engineers and panel builders, allowing them to tackle a wide range of applications.

Time is money, and the Busbar Bending Machine recognizes that fact. With its rapid bending capabilities, it can significantly reduce the time required for busbar preparation. This translates into quicker project completion and substantial cost savings. The machine’s ability to bend busbars accurately on the first try minimizes material wastage, further contributing to cost-efficiency.